Top 10 Injection Machine Robots You Need to Know About?

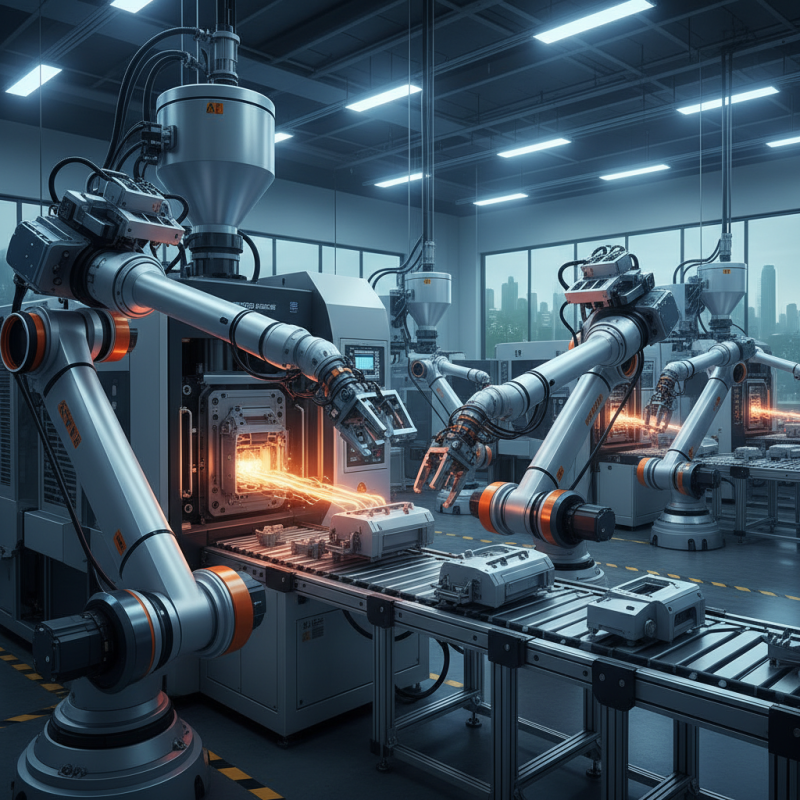

The rise of automation in manufacturing has changed the landscape significantly. Among these advancements, the Injection Machine Robot stands out. According to industry reports, the global market for robotic injection molding is expected to grow by 12% annually through 2025. These robots improve efficiency and precision in production processes.

Many manufacturers are now adopting Injection Machine Robots to enhance production capacity. These robots can operate continuously, reducing labor costs and time. In addition, they minimize waste, contributing to sustainability. However, the initial investment can be a barrier for some companies. They must weigh the long-term benefits against upfront costs.

The implementation of Injection Machine Robots comes with challenges. Integrating new technology into existing systems can be complex. There is also a need for specialized training for operators. As industries evolve, companies must reflect on how to best leverage these advancements. Future success may depend on their adaptability and willingness to invest in such innovations.

Overview of Injection Machine Robots and Their Applications

Injection machine robots are transforming various industries with their precision and efficiency. These robots automate the injection molding process, which is crucial for producing plastic parts. They are widely used in automotive, electronics, and consumer goods manufacturing. The intricate movements of these robots ensure that every part meets strict quality standards.

These robots handle materials consistently. However, programming them requires skill and experience. There is a steep learning curve, which can be daunting for new operators. Proper maintenance is also essential to avoid costly downtime. Many facilities struggle with this aspect, leading to operational hiccups. Despite these challenges, the potential benefits are enormous. Implementing these robots can significantly reduce cycle times and increase production rates.

The future is promising but requires adaptation. The ongoing integration of AI and machine learning is redefining how these robots operate. Achieving a fully automated process is still a work in progress. Many companies face obstacles such as labor shortages and training needs. As industries evolve, continuous reflection on these operational challenges is necessary. This will ensure that injection machine robots remain competitive and effective in the manufacturing landscape.

Key Features to Consider When Choosing an Injection Machine Robot

When selecting an injection machine robot, key features determine performance and efficiency. Precision is crucial. According to industry reports, robots with a precision rate of over 95% can greatly enhance product consistency. Look for robots equipped with advanced sensors and feedback systems. This ensures accurate positioning and reduces waste.

Speed is another important factor. Fast cycles improve productivity. Many businesses report a 20-30% increase in output with high-speed robots. However, in aiming for speed, manufacturers must also consider the quality of the finished product. It’s a balancing act. A robot that excels in speed but compromises on quality may lead to higher rejection rates, costing more in the long run.

Flexibility is essential for adapting to various tasks. Many robots now handle multiple processes, reducing the need for several machines. However, the complexity can be a double-edged sword. Operators may require more training to manage advanced systems effectively. A focus on user-friendly interfaces will be beneficial. Evaluate your production needs thoroughly before investing to avoid costly mistakes.

Top 10 Injection Machine Robots: A Comparative Analysis

Injection machine robots are transforming various industries. They are designed to improve production efficiency and precision. Each type has unique features, making them suitable for different applications. Detailed analysis can reveal their strengths and weaknesses.

One key factor is speed. Some robots can operate at remarkable velocities. However, this often compromises accuracy. A robot may produce more units but at a cost. There is a fine line between quantity and quality. Another aspect worth noting is maintenance. Some machines require frequent upkeep. This can lead to unexpected downtime.

User experience plays a significant role in how effective these machines are. Training operators is essential. If workers struggle with the technology, it defeats the purpose of automation. Overall, while injection machine robots offer advanced capabilities, there are hurdles to overcome. Mixing efficiency with reliability is a challenge every manufacturer faces.

Innovative Technologies in Modern Injection Machine Robots

Modern injection machine robots are transforming the manufacturing landscape. These machines enhance efficiency and precision in production processes. With advancements in technology, they are becoming more autonomous and intelligent. The integration of AI allows for real-time adjustments during operation. This leads to better quality control and reduced waste.

Additionally, some robots feature advanced materials handling capabilities. They can manage heavier loads and complex shapes with ease. This capability is crucial for industries like automotive and consumer goods. However, the reliance on automation raises questions. Are workers losing their skills? How do we balance efficiency with the need for human oversight? These are challenges worth considering.

Moreover, energy efficiency is another critical area. Many modern robots are designed to consume less power. This not only cuts costs but also reduces the environmental impact. Yet, some designs still require excessive energy, prompting skepticism. The path forward demands a careful evaluation of sustainability. Ultimately, while technology offers impressive advancements, continuous reflection on its implications is necessary.

Future Trends Shaping the Injection Machine Robotics Industry

The injection machine robotics industry is rapidly evolving. Several trends are shaping its future. One key trend is automation. As manufacturers seek efficiency, robots are replacing manual tasks. This shift enhances precision and speed in production.

Another important trend is the integration of artificial intelligence. AI enables robots to learn and adapt to changing environments. This leads to improved decision-making and enhanced capabilities. The machines can now predict maintenance needs, reducing downtime significantly.

Tips: Embrace the shift to automation. Invest in training for your staff to work alongside robots. This step is crucial for a smooth transition in your operations.

Sustainability is also taking center stage. Companies are focusing on reducing waste during production. Advanced robotics can help reconfigure workflows, using less material. Challenges exist in balancing cost and sustainability goals. It requires thoughtful planning and strategy.

Tips: Regularly assess your production processes. Identify areas where waste can be minimized. Continuous improvement should be a key focus for all teams.