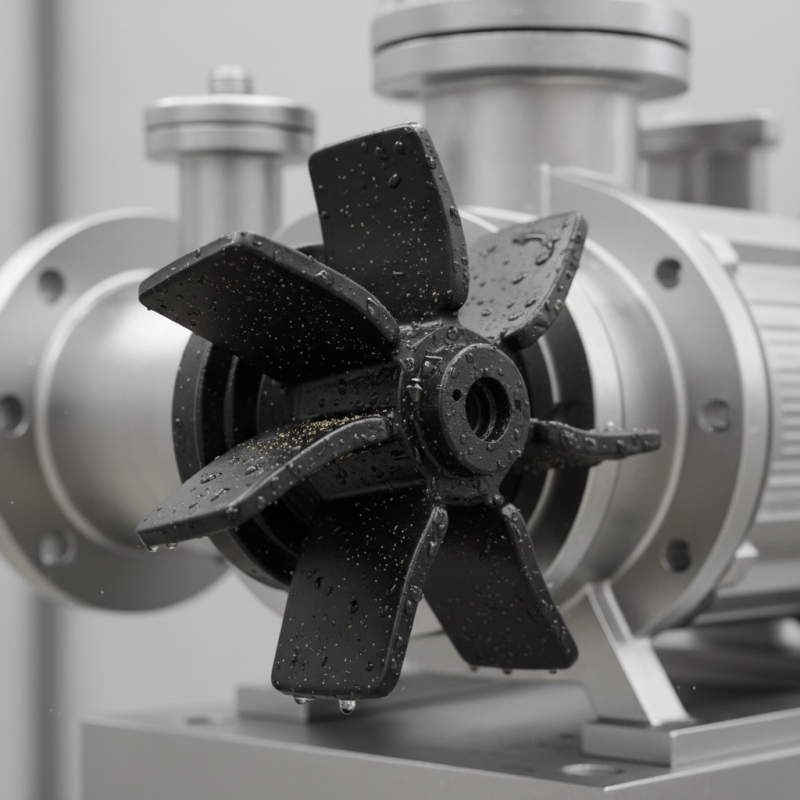

Why is Rubber Pump Impeller Essential for Fluid Transfer?

The Rubber Pump Impeller plays a critical role in fluid transfer systems. According to a report by the Global Pump Industry Analysis, the market for pumps is projected to reach $75 billion by 2026. A significant factor in this growth is the efficiency provided by high-quality components like the Rubber Pump Impeller.

In fluid dynamics, the impeller's design impacts efficiency and reliability. Studies show that rubber materials can enhance performance, especially in harsh conditions. The flexibility of a Rubber Pump Impeller allows it to handle abrasive fluids better than rigid alternatives. Yet, concerns about durability and wear arise. Although rubber can provide excellent sealing, it may require frequent replacements, leading to potential downtime.

Moreover, the environmental implications of material choice are becoming paramount. The demand for sustainable solutions is increasing. Companies face pressure to balance efficiency with eco-friendly practices. This necessitates reflection on the use of materials in fluid transfer mechanisms. The choice of a Rubber Pump Impeller, while beneficial, calls for ongoing evaluation of its lifecycle and broader environmental impact.

The Role of Rubber Pump Impellers in Fluid Transfer Systems

Rubber pump impellers play a critical role in fluid transfer systems. These components are essential for various industries, including agriculture, pharmaceuticals, and wastewater management. According to a recent industry report, rubber impellers account for approximately 30% of all pump materials used globally. Their ability to withstand harsh environments and maintain flexibility is crucial for effective fluid movement.

In fluid transfer applications, the choice of materials can greatly impact efficiency. Rubber impellers are often preferred for their resilience and compatibility with a range of fluids. They can reduce the risk of leakage and energy losses. However, not all rubber types provide the same performance. Some may wear down faster, leading to increased maintenance costs. This inconsistency requires careful selection based on specific application needs.

Moreover, the environmental factors also influence the performance of rubber impellers. Temperature fluctuations and chemical exposure can affect their lifespan. Data from the Fluid Transfer Industry Report shows that the longevity of rubber impellers can vary; in some cases, they may require replacement every year. Understanding these dynamics is vital for optimizing fluid transfer systems and ensuring reliability in operations.

Importance of Rubber Pump Impellers in Fluid Transfer Systems

This chart represents the key factors that highlight the importance of rubber pump impellers in fluid transfer systems. Each category signifies how essential it is for efficient fluid transfer, showcasing their efficiency, durability, cost-effectiveness, flexibility, and ease of maintenance.

Advantages of Using Rubber Material in Pump Impellers

The use of rubber material in pump impellers plays a crucial role in fluid transfer applications. Rubber impellers offer various advantages due to their unique properties. For instance, they provide excellent resistance to corrosion and wear. A study by the Fluid Pump Association found that rubber impellers can reduce maintenance costs by up to 30% compared to metal alternatives.

Additionally, rubber impellers have a high elasticity, allowing them to absorb vibrations. This reduces noise levels and enhances overall efficiency. According to industry reports, rubber impellers can improve flow rates by 15% in specific applications. This efficiency translates to significant energy savings for companies.

**Tip:** Always consider the specific fluid characteristics when selecting materials. High temperature or abrasive liquids might require different considerations.

Rubber impellers also have a lower specific gravity than metal. This quality makes them lighter, facilitating easier installation. However, not all rubber materials behave the same under stress. Some users have faced performance issues due to improper selection. Research shows that using the correct rubber compound can extend the lifespan of pump components significantly.

**Tip:** Regularly monitor pump performance to catch any early signs of wear. Implementing routine checks can help identify issues before they escalate.

Key Design Features of Rubber Pump Impellers

Rubber pump impellers play a crucial role in fluid transfer applications. They are designed to create movement within the fluid while maintaining efficiency. One key design feature is flexibility. This allows the impeller to adapt to different fluid types. It can handle varying viscosities, which is essential for different industries.

Another important aspect is the resistance to corrosion. Rubber materials are often used for their ability to withstand harsh chemicals. This property ensures long-lasting performance, reducing the need for frequent replacements. Additionally, the surface texture can greatly affect performance. A smoother surface can enhance flow dynamics, while a more textured surface can help in certain applications.

However, there are some challenges. Over time, rubber can degrade or wear out under specific conditions. Proper maintenance is crucial to prolong the life of an impeller. Regular inspections can reveal wear and prevent potential failures. In some scenarios, it might be necessary to reconsider the material choice for specific applications, especially in extreme environments.

Common Applications for Rubber Impellers in Fluid Transfer

Rubber impellers play a crucial role in various fluid transfer operations. These components are widely used in industries such as water treatment and chemical processing. The flexibility of rubber allows for smooth operation, reducing the risk of leaks. In pumping systems, they efficiently manage the flow of different fluids.

Common applications for rubber impellers include agricultural irrigation and wastewater management. In irrigation, they pump water from sources to fields. This ensures crops receive adequate hydration. In wastewater systems, rubber impellers move sludge and other materials through treatment processes. Their durability against harsh chemicals is essential here.

Despite their advantages, rubber impellers can wear out over time. Environmental factors contribute to this degradation. Regular maintenance is necessary to ensure optimal performance. Users should be aware of potential failure points. Understanding these aspects helps in prolonging the impeller's life and maintaining fluid transfer efficiency.

Maintenance and Longevity of Rubber Pump Impellers

Rubber pump impellers play a crucial role in fluid transfer systems, especially in industries like agriculture, water treatment, and chemical processing. Regular maintenance of these impellers can significantly extend their longevity. According to industry reports, maintaining rubber impellers can increase their service life by up to 30%.

Inspect the impellers for wear and tear. Look out for cracks and surface abrasion. These issues can affect performance. A simple visual check can save you from costly downtime. If you notice any degradation, it's essential to replace the impeller promptly.

Tip: Always clean the impeller after use to prevent fluid buildup. This practice can help maintain efficiency and reduce wear. Remember, rubber impellers might seem durable, but they require attention. Up to 20% of pump inefficiencies stem from neglected impeller maintenance.

Keep records of maintenance activities. Documenting inspections and replacements helps identify patterns in wear. This data can inform future purchases and maintenance strategies. It's a small effort that can lead to significant cost savings in the long run. Maintain diligence, and it will pay off.