Best Electric Ball Valves for Efficient Flow Control Options?

In the realm of flow control, Electric Ball Valves are becoming indispensable. They are efficient, reliable, and versatile. Industry expert Dr. Emily Carson notes, "Electric Ball Valves are transforming how we manage fluid dynamics." This statement captures the essence of their significance.

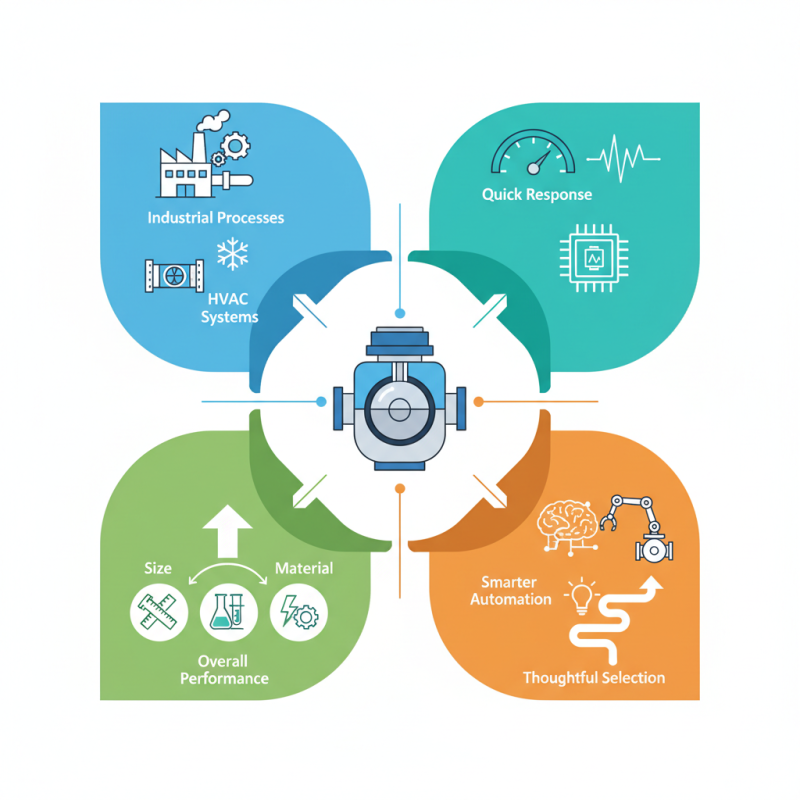

Electric Ball Valves offer precise control over fluid flow. They can be found in various applications, from industrial processes to HVAC systems. Their electronic actuation allows for quick response times. However, some users overlook the importance of proper installation and maintenance. A valve that is not correctly set up may lead to inefficient operations.

Understanding the features of Electric Ball Valves is crucial. Key aspects include size, material, and actuation type. These factors impact overall performance. There are nuances to each product. As technology advances, so do options for smarter automation. However, the learning curve can be steep. A thoughtful approach to selecting the right valve is essential for optimal flow control.

Overview of Electric Ball Valves and Their Functions

Electric ball valves are essential for efficient flow control in various industries. They utilize an electric actuator to open or close the valve, allowing for precise regulation of fluid flow. According to a recent industry report, the demand for electric ball valves has increased by 15% over the past three years. This surge is driven by the need for automation and improved energy efficiency in manufacturing processes.

These valves are favored for their quick response times and reliability. They can be operated from a distance, providing both convenience and safety. In fact, studies show that electric valves can reduce energy costs by up to 30% compared to manual valves. However, their installation requires careful consideration of electrical systems and compatibility with existing infrastructure. This complexity can lead to potential setbacks in project timelines.

Despite their advantages, users must account for maintenance. Electric ball valves can experience wear and tear, especially in harsh environments. A study revealed that nearly 20% of failure cases stem from improper installation. Therefore, investing in training and proper maintenance schedules is critical. While they offer significant benefits, the upfront costs and technical requirements may pose challenges for some organizations.

Benefits of Using Electric Ball Valves for Flow Control

Electric ball valves are becoming popular for efficient flow control in various applications. They offer significant benefits over traditional manual valves. One major advantage is their ability to provide precise flow regulation. This precision helps in maintaining the desired flow rate with minimal fluctuations. Operators can enjoy enhanced control, especially in complex systems.

Another strong point is automation. Electric ball valves can integrate easily with control systems. They can respond instantly to commands from sensors or PLCs. This rapid response improves system efficiency and avoids delays. However, it is essential to ensure proper calibration. Wrong settings can lead to flow issues.

The energy efficiency of these valves also stands out. They often require less energy to operate than other types of valves. With their durable construction, they can handle high pressures well. Maintenance is necessary, but electric ball valves often require less frequent service than conventional options. Users need to monitor their performance closely to realize their full potential.

Key Features to Consider When Choosing Electric Ball Valves

When considering electric ball valves for efficient flow control, there are crucial features to evaluate. One significant factor is the valve's precision. A study from the Institute of Fluid Control shows that valves with high accuracy reduce waste by up to 20%. Look for models that offer precise positioning and quick response times.

Another essential aspect is the materials used in construction. Valves made from corrosion-resistant materials tend to last longer. A report from the American Society of Mechanical Engineers indicates that about 30% of ball valve failures are due to material degradation. Consider valves with Teflon or stainless steel components for enhanced durability.

Tips: Check compatibility with your fluid types. Not all electric ball valves can handle aggressive chemicals. Research how the valve will perform under varying temperatures and pressures. Regular maintenance can prevent unexpected failures.

When choosing, think about the operating voltage. Some systems require standard voltages, while others may need specialized power. Balancing efficiency and energy consumption is vital. Improper selections can lead to increased operational costs.

Best Electric Ball Valves for Efficient Flow Control Options

| Model | Size (Inches) | Voltage (V) | Material | Flow Rate (GPM) | Operating Temperature (°F) |

|---|---|---|---|---|---|

| Electric Ball Valve A | 1 | 24 | Brass | 15 | 140 |

| Electric Ball Valve B | 2 | 120 | Stainless Steel | 25 | 185 |

| Electric Ball Valve C | 1.5 | 230 | PVC | 30 | 120 |

| Electric Ball Valve D | 3 | 12 | Aluminum | 40 | 200 |

Top Brands and Models of Electric Ball Valves Available on the Market

When it comes to electric ball valves, efficiency and precision are key. These devices provide reliable flow control in various applications. They come in different styles and materials, catering to diverse needs. Most electric ball valves feature an easy on/off operation. However, careful selection is vital.

Many models include smart features. Some allow for remote monitoring and control. It’s crucial to check compatibility with your existing systems. Ensure the voltage and control signals match your requirements. Not every model suits every situation. Some may lack durability in harsh environments. Conduct thorough research before making a decision.

Tips:

Pay attention to the valve’s size and specifications. Proper sizing affects flow rates significantly. Installation can pose challenges. Engage a professional if needed. Ultimately, refining your choice means considering both the technical aspects and real-world application. This balance leads to better flow management, preventing unexpected issues in the future.

Installation and Maintenance Tips for Electric Ball Valves

When installing electric ball valves, proper placement is crucial. Choose a location that allows easy access for maintenance. Keep valves away from extreme temperatures or vibrations. Ensure that the power supply is stable and compatible. Check the orientation of the valve. Incorrect installation can lead to flow issues or damage.

Routine maintenance is essential for longevity. Regularly inspect electrical connections for wear and tear. Look for corrosion or loose wires. It's important to clean the valve to prevent blockage. Sometimes, users forget this step. This can cause poor performance over time. If you notice any unusual noises, examine the actuator immediately. Addressing small issues early can prevent larger problems later.

Proper calibration is also necessary. Misaligned settings can affect flow control efficiency. Periodically verify the calibration adjustments. However, it can be daunting for those less familiar with the technology. It’s okay to seek professional help. This ensures that everything operates smoothly and efficiently. Don't overlook these steps, as they are key to maximizing your investment.