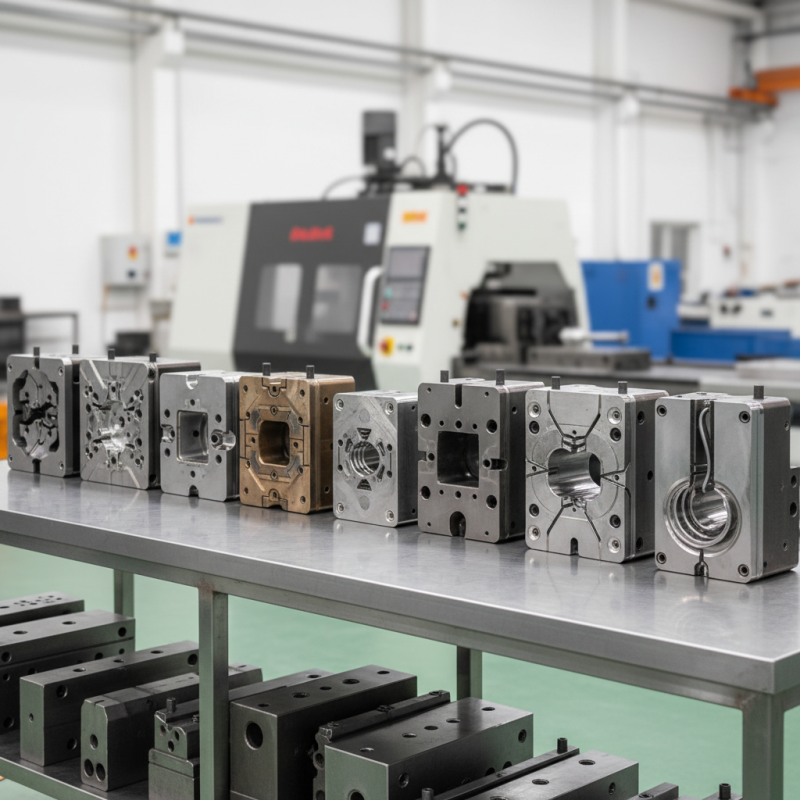

10 Best Die Casting Molds for High Quality Production?

Die Casting Molds are crucial for high-quality production in various industries. They determine the precision and finish of the final product. Selecting the right die casting molds can enhance productivity and reduce costs. However, not all molds perform optimally under different conditions.

Manufacturers often face challenges when choosing molds. Some molds may wear out quickly, leading to defects. It’s essential to evaluate the material and design of each mold. Wear and tear can significantly impact the mold's longevity. Moreover, the cooling time and ejection process need careful consideration. These aspects are vital for maintaining quality standards.

Through this guide, we will explore the ten best die casting molds. Each option will be examined based on various factors. Attention to detail is key in this selection process. Investing in high-quality molds pays off in the long run. However, it’s equally important to learn from past experiences and continually assess mold performance. A reflective approach can lead to remarkable improvements.

Overview of Die Casting Molds and Their Importance in Production

Die casting molds play a fundamental role in high-quality production. They create precise metal parts for various industries. The quality of these molds directly affects the final product. If the mold has defects, the parts will also be flawed. This leads to waste and higher costs down the line.

Choosing the right materials for die casting molds is crucial. Steel alloys generally provide durability. However, using high-quality steel can significantly increase initial costs. It's a balance between quality and budget. It's important to assess the production volume to determine the best option. Molds may wear out over time. Regular maintenance can prolong their lifespan.

Tips: Consider testing molds with small batches first. This helps identify potential issues without huge investments. Monitor the temperature during the casting process. Uneven temperatures can lead to defects. Keeping an eye on these factors can improve efficiency.

Types of Die Casting Molds: An In-Depth Comparison

Die casting molds are crucial for high-quality production in various industries. There are different types, each serving unique purposes. The most common types are sand molds, permanent molds, and shell molds. Each has specific benefits and limitations. For example, sand molds are versatile but may lack the precision needed for intricate designs.

In a recent industry report, it was found that over 30% of die cast products suffer defects due to mold design flaws. This highlights the importance of choosing the right mold type. Permanent molds typically offer better durability and accuracy but can be more expensive. Meanwhile, shell molds are lightweight and provide good surface finishes. However, they may not withstand high-pressure applications.

When evaluating molds, factors like production volume and material type are essential. A mold designed for aluminum might not perform well for zinc. This mismatch can cause significant issues. Understanding these nuances can prevent costly mistakes. Despite advancements, the industry still grapples with quality control issues. Continuous improvement in mold design is vital for maintaining high production standards.

10 Best Die Casting Molds for High Quality Production

Key Features to Look for in High-Quality Die Casting Molds

When looking for high-quality die casting molds, consider the material first. Steel molds are durable and can withstand high pressure. They provide better precision and a longer lifespan. Aluminum molds are lighter and heat up quickly but may wear out faster. The choice can affect production costs and output quality.

Another essential feature is the mold design. Complex shapes often require intricate details in the mold. Achieving the right balance between complexity and ease of release is crucial. Poor design can lead to defects. It’s a common oversight, resulting in wasted materials and increased cycle time.

Cooling systems within molds play a vital role too. Efficient cooling leads to better surface finishes and faster production cycles. Look for molds with optimized cooling channels. This can enhance performance but may complicate the mold structure. Ultimately, fine-tuning these elements can be a challenge but is necessary for high-quality outputs.

10 Best Die Casting Molds for High Quality Production

| Mold Type | Material | Max Temperature (°C) | Surface Finish | Cycle Time (seconds) | Lifespan (cycles) |

|---|---|---|---|---|---|

| Cold Chamber Die Casting | Aluminum | 700 | Smooth | 60 | 500,000 |

| Hot Chamber Die Casting | Zinc | 450 | High Gloss | 30 | 1,000,000 |

| Gravity Die Casting | Copper | 800 | Semi-Smooth | 120 | 300,000 |

| Die Casting with Inserts | Magnesium | 600 | Textured | 45 | 700,000 |

| Thin-Walled Die Casting | Aluminum | 750 | Smooth | 50 | 400,000 |

Top 10 Recommended Die Casting Molds for Enhanced Production Quality

Die casting molds are crucial for achieving high-quality production. Selecting the right mold affects the final product's quality and durability. Quality molds should feature robust materials. They should withstand high pressure and high temperatures. A good mold provides consistent results, but not every mold meets these standards.

When choosing a die casting mold, consider design complexity. Intricate designs may lead to defects if the mold isn't precise. Surface finish also matters; rough finishes can indicate a poorly made mold. Regular inspection is necessary to ensure molds remain in good condition. Sometimes, unexpected defects arise, causing production delays. Adjustments can be cumbersome, reflecting a need for better quality control.

Evaluating the molds based on your production needs is vital. The right choice boosts efficiency and product reliability. However, it’s also important to learn from past experiences. Each mold tells a story; some work excellently, while others require changes. Adopting a mindset of continuous improvement enhances production quality over time.

Maintenance Tips for Extending the Life of Die Casting Molds

Maintaining die casting molds is crucial for high-quality production. Regular cleaning is essential. Use appropriate solvents and brushes to remove debris and residues. Neglecting this can lead to defects in cast products. It is also important to inspect molds frequently for wear and tear. Look for signs of corrosion or cracking. These can significantly affect the mold's lifespan.

Lubrication should not be overlooked. Proper lubrication reduces friction during the casting process. It helps in achieving smoother operations. However, apply the right amount; too much can attract dust and debris. Temperature control is another vital aspect. Excessive heat can warp molds, leading to costly replacements. Ensure that molds are cooled adequately after each use.

Training employees on proper handling is often forgotten. Molds are sensitive and require careful handling. Accidental drops can cause irreparable damage. Documenting maintenance schedules can help track mold condition. This practice allows early detection of issues. Regular reflection on these practices can lead to improvement. Maintaining molds is not just about preserving machinery; it's about ensuring quality and efficiency in production.